Monopole®

The Audio Terminals / Pure Copper Binding Posts.

Why the Monopole®?

It all started in 1983/4 when I was involved

in the design and fabrication of water electrolysis welders. These devices

used a small cylindrical cell with interlocking positive and negative mild

steel electrodes immersed in a NaOH bath. The bath was automatically topped

up with water as its water level was depleted by virtue of the effect of

the electrolysis. Hydrogen and Oxygen were electrolysed in the same cell

and the gas mixture was burnt in a standard oxy/acetylene torch. Its temperature

being considerably higher than a normal oxy/acetylene flame. But there

was one constantly recurring problem with this apparatus. Despite the high

current : 120 Amperes, the power signal from the supply transformer would

often fail to reach the electrolysis cell. This primarily due to the low

voltage being used: 2 Volts. The slightest bit of grease or grime on the

contactor would void the transmission of the electrical signal. Being a

keen audiophile at the time, it occurred to me, what if the same thing

could be happening in the audio chain. Thus began the process of investigating

whether the information carried in the audio pathways from source to speaker

was degraded at its interface changes. The answer soon became quickly evident:

Yes! So what to do from here!

1987

The BMNP-M11

was made from assembling off the shelf componentry and a few custom-made

parts, in an effort to begin the process of eliminating or minimising the

effects of signal deterioration at one of the critical interface signal

transfer points; i.e. from the amplifier to the loudspeaker. The M1 did

exhibit some improved response but not of sufficient significance so as

to be able to say that there was clearly some considerable improvement

in the quality of reproduction. The paradigm was tinkered with for the

next 4 years .

1991/92

The M2, M3 ? M4:

All subtle variants of each other and each

seeking to achieve a particular design target, were inevitable steps in

working through predetermined mind-sets as to how the target was to be

achieved.

At first it appeared that the surface area

across which the signal was transmitted was a critical parameter, next

it became apparent that the type of conductor being used was also significant.

If the surface area of the transmitting surface

and receiving surface were considerably increased there should be some

measured improvement in the quality of the signal transferred. Against

what was this to be measured? The voltage and current transfer appeared

to be identical ‘fore and aft’ of the transfer interface; yet there was

an appreciable improvement in the perception of the quality of the information

being reproduced ( as the surface areas at the transfer interfaces were

increased)2 . It was also beginning to

become apparent that there was an improvement curve of the quality of reproduction

as each design variant evolved from its predecessor.

The evolution being from Brass to Bronze and

then to Copper as with the M5.

1992/93

M5

First drift from the mind-set. The M5. This

was a bolt centred device in which a bolt secured the wire into the body

of the Monopole®. Each of the input and output sections were mirrored

around a central flange and separated by only 10mm of copper. This was

the first considerable quantum improvement in sound quality from the first

4 previous designs. The M6 and M7 soon followed. These, though were too

bulky and the M8 ( which was never built ) was bigger still. Neither the

M6 nor M7 proved to be an improvement on the M5. So the M9 was born. 1993/94

M9

The M9 was a straight piece of 25mm diameter

copper billet that was tapped into at each end with an M16 thread and separation

between conducting faces of 12mm. It was as close in design to the M5 as

one could be. It was also an improvement and easier to adapt though not

very practical from a commercial point of view, due to the fact that there

was only one bolt and insertion hole at either end for bare wire. Everyone

to whom it was shown cried: What about spades, bananas etc.. What was beginning

to become apparent through the separate designs of the M9 and M5, was that

the optimum performance for an audio binding post at the interfaces covered

by the binding post could only be achieved through a particular design

paradigm since patented by myself and the common design paradigm throughout

the current production Monopoles®. This has since been the principle

design paradigm of all subsequent Monopole® after the M10.

M10

The M10 was the first attempt to address ease

of installation of the Monopole® into its appliance with the first

use of a twin-bolt mechanism. This accommodated all manifestations of connectors

and wire endings, but diverged from the new design philosophy of accommodating

bare-wire within the appliance bolted directly into the body of the binding

post. The M10 had a threaded shaft ( in its internal to the appliance section

) for securing nuts and solder lugs for the internals of the appliance

. Audio did not sound as well as for the M9 or M5.

1994/5

M11

1995

M12

Many who saw the M11 asked for a smaller version.

The M12, identical in topology to the M11 but a few sizes smaller showed

that it is not possible to fabricate scaled down sizes of the M11 design

cheaply. The only cost benefit was the reduction in the material costs

and some reduction in the electroplating costs. Even though the M12 was

of identical topology to the M11 it did not sound as ‘Transparent’ as the

M11. The M12 was not added to the current line-up for this reason.

The M12 is discontinued but was an important

design step to the M26 described below.

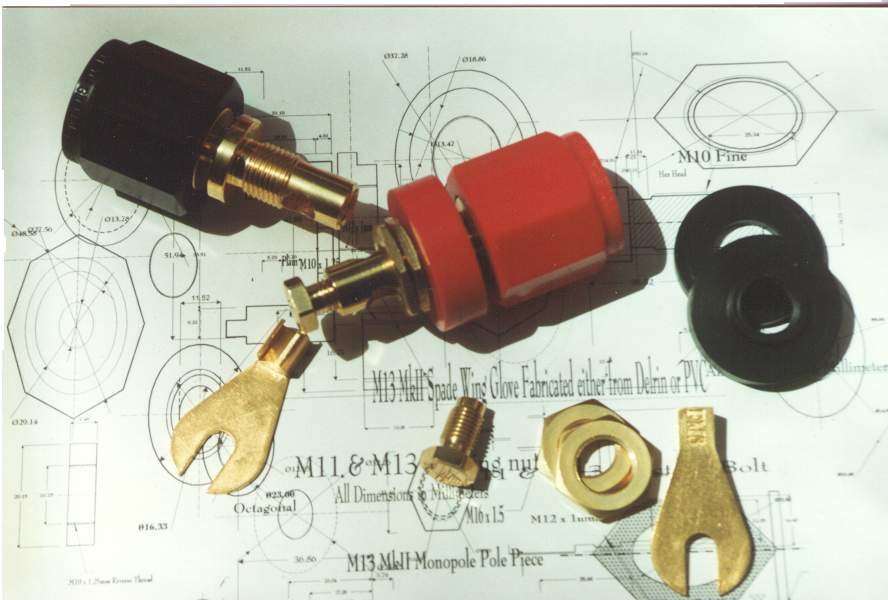

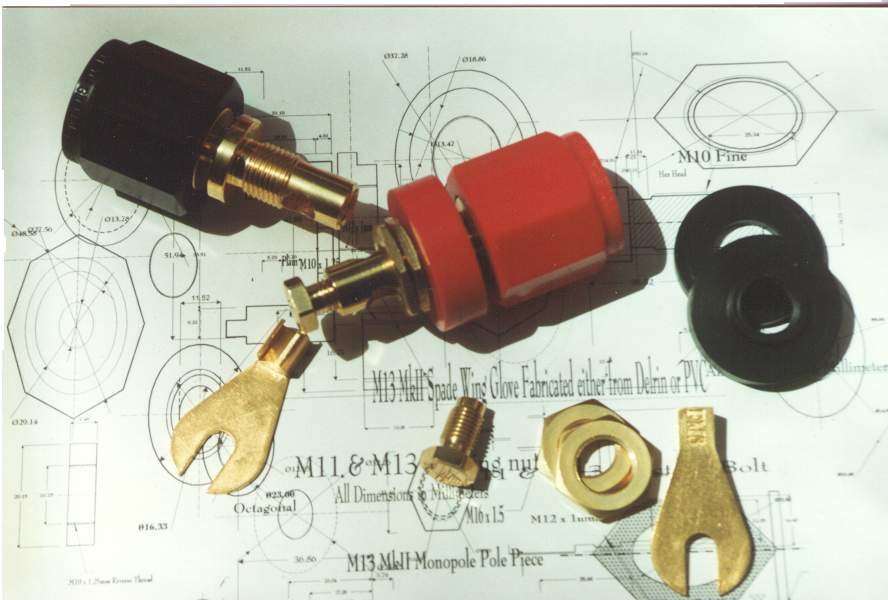

The M13 and

IEC-65 and IEC-CE

With the advent of the imposition of IEC-65

in Europe in 1996 the M135

was designed. It meets all the requirements of the new IEC-65 standard

but departs only slightly from the original design criteria of the Monopole®

as primarily a ‘bare-wire’ binding post. It will accommodate bare wire

but is a return to the shaft centred design of the M1-M4 with the refinements

of the M11. Internally ( in its fitted appliance ) the M13 is identical

in size and configuration to the M11. Externally its Nut is fully insulated

and can only be screwed out to a maximum of 3.8mm. The M13 is the largest

of all the current production Monopoles®. Its external diameter is

41mm and external signature6 on its working

appliance is 45mm.

In my listening tests the M13 stands out from

the other designs that are mentioned here. It is also the most expensive

of all the Monopoles® to fabricate. In a series of blind tests the

M13 gives the reproduced audio signal just that much more sense of presence

and intimacy. Perhaps the insulation acts to minimise mutual inductance

between binding posts. The other binding posts are, though, better than

any other audio binding post available anywhere in the world today.

Much of the design and evaluation of the M13

? M14 was done in the quiet of the country side more than 100 kilometres

from the nearest city and high in the Great Dividing Range mountains in

South Eastern Queensland. My noise meter reading the background

noise down to a low 18db on the stillest nights and averaging around 22db

- 26db on normal windless nights. With these levels of background noise

it becomes easier to appreciate the dynamic range capable of a CD but also

to appreciate the amount of information that a record stylus is able to

glean from a vinyl record.

Nuances and subtle differences between different

components that may offer even the subtlest of improvements can be compared

and evaluated. It was in this environment that there was a distinctive

‘blooming’ of the reproduction of the audio signal with the M13. The M11

and M14 were a close, very close second.

Though it would be easy to

consider my judgement somewhat biassed, I believe that the M13Mk IV ? V

variants are the best audio binding posts ever fabricated. The M13 is the

best of the best.

To view a low resolution

image of the M13 MkV click on the image.

IEC-CE

The M13 MkV is fully IEC-CE compliant. It

has no provision for banana connectors and is solely a spade binding post.

It only opens out to a maximum of 3.0 +/-0.5 millimetres

M14

M26

( The Feral Fox )

This is the barest bone Monopole®. All

the fastening and assembly components for all the other Monopole® designs

are fabricated especially for each model to ensure complete accuracy for

installation and performance.

The M26 does not use the junction assembly

for the securing of the internal appliance wire; instead it uses two M4

grub screws securing the appliance wire into a 5.0mm diameter x 26mm long

hole into the body of the pole piece.

Standard off the shelf nuts and M4 Stainless

Steel grub screws are supplied with each M26 Monopole®.

UHMW/PE insulators with A single SS locking

nut secures the M26 Monopole® securely into its appliance; whether

it is an amplifier or a loudspeaker, the M26 will deliver an improved

the performance on any brass connector or higher alloy copper connector

because the M26 Monopole® is made from Pure Copper.

Colour coded polarity indicators are also

supplied.

This Monopole® will accept standard spades

( with fork tongs > 7.0mm ) and also the FM21.

Click here to

see an image of the M26

Richard Fung, audiophile, comments on the

benefits of the M16

(This was the previous iteration of the M26.)

Banana's

Banana connectors have been banned in all

IEC-CE signatory countries. For this reason all Monopoles® are available

with or without provision for banana connectors. In Europe where a more

stringent application of IEC-CE has been enforced only the M13 MkV Monopole®

meets this standard. And is the only binding-post that does!

COMMON

PROPERTIES OF THE M11; M13 ? M14 MONOPOLE®.

All Bocchino Audio Monopoles® will handle

up to 200 Amperes ( continuous )12 1314With

transients up to 1200Amperes for as long as 100 milliseconds. Amplifiers

and loudspeakers that claim current capacities of up to + / - 600 Amperes15

are easily accommodated by all the current Monopoles®. This high current

capacity also allows extremely low power signals effortless passage through

the Monopole®. Face to face resistance along the shortest path16

is less than 5 Micro Ohms 1718.

To view the current versus temperature graph

click the duck. The temperature is in Degrees Celsius and current in Amperes.

The graph following is for M11 M13 and

M14 Monopoles® is an 61Kb .Jpeg document.

for Current carrying capacity graph for M12

/ M26 / M22 and M24 Monopoles® ( 82 Kb image ) click image>

G: Installation

Hole

ALL Monopoles® require

a 21mm hole in their operational appliance to be installed. The Nose of

the Mounting threaded shoulder washer is 20mm in diameter on all Monopoles®.

Hole centres should be a nominal 50 millimetres.

( This also applies to the M26 Monopole®

)

The improvement in the quality of sound reproduction

is a consequence of the high quality of materials, fabrication craftsmanship

and the large contact surface areas and especially the elimination of solder19

at the most important "transition" connections of the respective appliances

to which the Monopoles® are attached. The elimination of this resistive

connection at the appliance transition interface has an extremely dramatic

effect on the quality of audio reproduction. Transients are more immediate

and faster, thus reducing colouration to the point that many have called

the Monopole® the only transparent window to the true workings of ones’

audio appliances. Silences where they should be, crescendos that don't

hang around and musical instruments that sound like their real-life selves

and not like sine-waves.

Audio sounds as if it has been released from

a choking constriction. Music is freer, extended and more open, taking

the listener a quantum leap closer to the original performance. Instruments

do not appear as points in the stereo holographic image but as three dimensional

fields representative of their size and location. Timbral accuracy is closer

to the original live audition and vocals are presented with crisper diction.

Monopoles® put the endings on the words.

Better still. Try them. The caged canary becomes

the soaring condor.

In using firmly clamped unsoldered bare

wire all the way from the amplifier to the loudspeaker transducer, with

minimal componentry in the signal path, the quality of reproduction is

as close to live as modern technology allows .

Welcome to the ‘private space’

of the original performance.

Enjoy!!!!!!!!!!!!!!!!

Regards

Carmine Bocchino

( Design Engineer and Governing Director of

Bocchino Technologies )

Goto Monopoles®

Pricing.

Return to Bocchino

Audio contents page

Note1

BMNP standing for " Bocchino ‘Monopole®’

".

Note2

Incremental increases in the surface area

transfer interfaces demonstrated that there was a considerable improvement

in both quantity and quality of signal transfer up to 25mm in diameter

after which though there were ‘perceptible’ improvements in 50mm and larger

the degree of improvement did not warrant the expense and was also not

as noticeable as the improvement from 6mm dia to 25mm dia.

Note 5

Note6

The external signature is the amount of millimetres

that the Monopole® sits proud of the appliance interface.

Note7

The M14 has the smallest external signature

of all the Monopoles®.

Note8

At the spade insertion interface the M13 variants

locking nut and mating insulating washer are round to allow perfect trimming

of insulation on the spade lug.

Note9

Delrin is an Acetyl based polymer adapted

from the electrical transmission industry where it is used to isolate extremely

high voltage and high current carrying cable.

Note9b

Nickel has a distinct property in that in

the presence of an electrical field it will retain some residual magnetism.

This property is known as the Hall Effect! And inhibits the efficient transmission

of the audio signal thus leading to some signal degradation. It begins

from the second an electrical begins its transit through any connector

that has a Nickel substrate. One needs to demagnetize ones system on a

regular basis to counter the build up of this residual magnetism within

the Nickel plate layer. Where the signal path transition points are all

Bocchino Audio components there is no Hall-Effect and hence the system

will always sound open and whole because it is in a state of being ‘permanently

demagnetized'.

Note10

Pure Silver

has an electrical conductivity of 0.630 106/cm-Ohm

105.7% that of Copper.

Pure Copper

has an electrical conductivity of 0.596 106/cm-Ohm

100% that of Copper.

Pure Gold

has an electrical conductivity of 0.452 106/cm-Ohm

75.8% that of Copper.

Rhodium

has an electrical conductivity of 0.211 106/cm-Ohm

35.4% that of Copper.

Nickel

has an electrical conductivity of 0.143 106/cm-Ohm

24% that of Copper.

Brass

has an electrical conductivity of 0.137 106/cm-Ohm

23% that of Copper.

Tin

has an electrical conductivity of 0.092 106/cm-Ohm

15.4% that of Copper.

Carbon

has an electrical conductivity of 0.00061 106/cm-Ohm

0.102% that of Copper.

Hence Silver is the best room temperature electrical conductor in the known

universe: followed by Copper and then Gold. Gold has the distinct advantage

in that it does not corrode and hence electrical contacts plated with Gold

remain corrosion free for most of their working life and conduct the electrical

with minimum distortion or heat dissipation. ( Gold has an albido of 1:

it gives what it gets ).

Brass and Nickel used in standard audio electrical

binding posts each have conductivities 4 times less than Copper or Silver.

Doubtless economics and fashion plays an important part in the choice of

materials. Not every manufacturer will fabricate their componentry

from the best available materials;l but with good marketing you can sell

anything!

Presently room temperature super-conductors

are not yet available. We are stuck with Copper, Silver and Gold; which

I think will do for the time being.

If you want an independent opinion on the

electrical and other properties of the elements download the Periodic Table

Software from SMI Software

site .

Or go to the Web

elements by clicking these links.

Note11

Silver Copper has a conductivity of 100% -

102.5% that of Normal Copper and a machinability index of 20; It contains

a minimum of 0.5% Silver.

Note12

Calculated using: R=( r x L )/A ; W=I2R

; dT= (W/3.6)/(M x c).

Note13

110 A continuous results in dT=0.5OC

; 220 A continuous dT=2OC. Normal listening will not

cause any perceptible temperature rise.

Note14

Acceptable factors of safety deem that the

true domestic operational duty of Monopoles® not exceed 200 Amps continuous

with 400 amps for no more than one second. The 1200 amp rating has a factor

of safety of two whereas the operational duty of 200 Amps continuous has

a factor of safety of 12. This being the more prudent and common sense

rating. The top rating of 1200 Amps should be for transients lasting no

more than 100 milliseconds @ 30 second intervals ( music just doesn't get

this powerful ). Amplifiers with +/- 600 Amps are still acceptable appliances

for Monopoles® to be used on; provided that their output does not exceed

the safety margins of the Monopoles®’ specification listed here.

Note15

Current swings of up to 1200 Amperes.

Note16

Calculated for HCOFC Copper.

Note17

To the Bare wire interface for the M11 and

to their respective spade faces for the M13; M14.

Note18

Monopoles® are for use only on audio equipment

and not for use on high current machinery such as arc welders. Nor should

Monopoles® be subjected to continuous high current over and above their

specified rating.

Note19

Solder is a more resistive material than the

metals that it seeks to join. In fact even Silver solder is over 50 times

more resistive than normal silver. Most solder used in the electrical industry

is lead/tin based and this is over 100 times as resistive as copper.

Note 20

UHMW/PE is the acronym for Ultra High Molecular

Weight Polyethylene ( an atomic weight of each of the molecules is nominally

over 4000000, being composed of very long Polyethylene chains ).

Goto: http://www.boedeker.com/

for more complete information on plastics and polymers