After over 30 years of designing Pure Copper connectors ( considered by the industry as the best in the world ) for the High End Audio industry, Bocchino Technologies now designs, manufactures and supplies Pure Copper Battery Terminals. As there are a huge number of different battery nipples onto which terminals are fitted, the BocchlugTM is a custom designed component. There are also many different means of securing the BocchlugTM to the battery nipple. Standard grasp is via a tightening clamp, but Bocchino Technologies can adapt almost any method for securing the BocchlugTM onto its fitted to battery nipple.

There are three options for theBocchlugTM :

- Firstly the Standard Model1 is milled from 99.99% Pure Copper; Heavily

Silver electroplated and then Gold plated to inhibit corrosion.Secondly,

there are many instances where a cast copper terminal is the most economical

option: Standard Model2.Thirdly, Almost any metal, that exhibits

electrical conductivity, can be milled or cast into a battery terminal;

specialist materials for battery terminals include De-Zincified brass (

excellent for environments where corrosive atmospheres are present ) Better

still for difficult environments are a host of Bronze alloys: Tobin Bronze,

Phosphor Bronze and many others tailored to required electrical properties

as client specified. Additionally dependent on the environment SS316L

( though a poor electrical conductor is excellent in its anti corrosion

resistance ) and for out of this world: Tungsten-Copper in client specified

ratios for interplanetary travellers!Fourthly: The reason for choosing

Copper Alloy C10100 ( identical alloy used on the Large Hadron Collider

in Geneva and many other advanced physics appliances ) is its unparralled

electrical conductivity: 101% IACS and its unconditional stability.

All C10100 terminals are Virgin alloy and mill certified; no shortcuts!

Standard Model 1

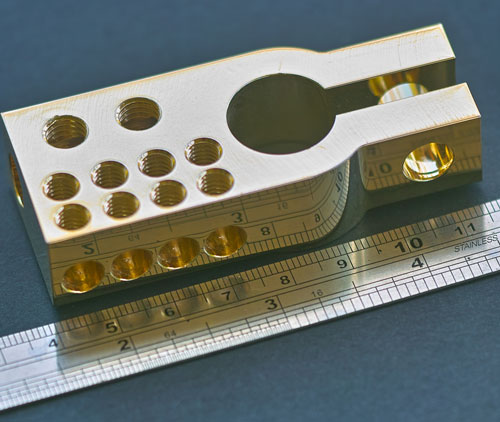

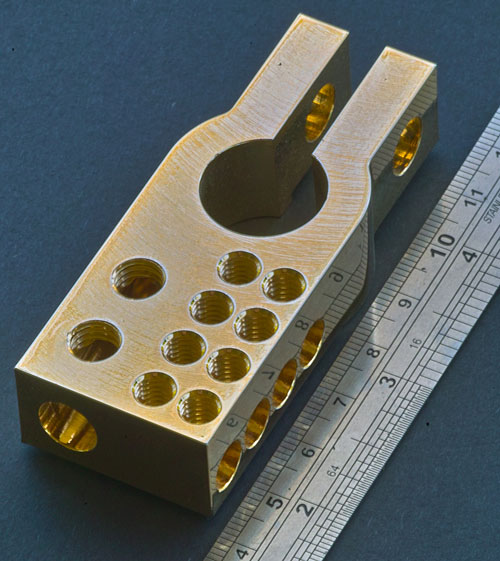

Standard Model1 ( SM1): Milled From Pure Copper ( C10100 99.996% Pure Copper ) with thick Silver electtroplate ( 11 microns + ) and top electroplate of Gold. the SM1 has a single 30mm deep x 9mm diameter main 2 x M8 Stainless Steel Set Screws hold the wire core in place. There are also 4 x 16mm deep x 7mm diameter secondary galleries with 2 x M6 Set screws per gallery holding respective inserted wire cores secure. All set screws are 304SS and these can be upgraded to 316SS or Titanium; the options are large. With discrete galleries ( 5 in all ) the SM1 makes it easier to apply different wire cores as needed; very helpful when aftermarket fitting of car stereos and similar additional accessories requiring efficient access to the battery's' electrical output.Dimensions of the StandardModel1 are: 76mm long x 30mm wide x 18mm high: Milled Pure Copper!

Imperial dimensions: Approx: 3ins long x 1 5/32 ins wide x 11/16 high.

Where there is a requirement for larger wire cores to be secured into the BocchlugTM the BocchlugTM is fully customiseable to client requirements and any number of discrete insertion galleries and any diameter for the main power wire is easily accommodated. Additional secondary galleries are customiseable to client requirements but the StandardModel1 is the core design.

StandardModel1's can be supplied in identical alignment or mirror alignment

StandardModel1 is designed for the automobile battery but is easily adaptable for marine, heavy vehicle and military applications and has a lateral lay.

Pricing: $USD 88.00 per terminal.

|

|

Standard Model 2.

Designed primarily for the solar and renewable energy industry the SM2 has a narrow footprint. From the nipple clasp the terminal then turns vertically for securing the heavy duty wiring associated with deep cycle batteries. The SM2 is made by casting Copper at 99.9% purity resulting in a final purity of 99.3% ( consequent to the casting method where bismuth is used as a flow agent ) and an IACS of > 99%. The SM2 comes standard with a single wire gallery to client specification and can be from 6mm diameter up to 32mm diameter ( or larger ) depending on client specification. The SM2 is also heavily Silver electroplated with optional top finish of either Palladium or Gold. Top surface electroplate is intended for protection against corrosion. In addition to the single main wire gallery the SM2 can be supplied with additional discrete galleries to meet client requirements. Depending on the quantities these are either milled from Pure Copper C10100 or cast; Where asked the SM2, while exhibiting a vertical lay can also be supplied in a horizontal lay or angular lay as deemed by client application.Advantages of the Bocchino Technologies Battery Clasp:

Milled from Pure Copper ( or cast as in the SM2 ) there is a quantum improvement in electrical conductivity efficiency both into and out of its fitted to battery. In terms of IACS the electrical conductivity of the pure copper used in the BocchlugTM : C10100 Copper ( 99.99% Copper ), is 101%. Brass terminals used on nearly any vehicle have an IACS of <23% and even lower where the brass is heavily doped with lead.

The consequence to the end user of the BocchlugTM is that there is faster startup, and recharging is more efficient. The BocchlugTM will last a very long time and comes with the only warranty ever offered to a battery terminal in this industry of 5 years guarantee against poor workmanship. With the BocchlugTM installed, vehicles also run quieter and charging components ( alternator or generator ) also run quieter and more efficiently. For arrays of solar deep cycle batteries, there is far less 'hum' characteristic of such huge arrays. If you operate a diesel-electric submarine you will find the batteries run cooler and charge faster.

Bocchino Technologies Battery Clasps can be designed for automobile,

mining, renewable energy storage, marine, military and spacecraft applications;

along with many other domains.

For more information please contact Bocchino Technologies: